Multi Pole Injection Ferrite Magnet

1.Material: PA6 Base resin+Ferrite Magnetic Powder

2.Dimensions: According to your requirements

3.Grade: MF-618,MF-620 and etc

4.Max Operating Temperature: -20°C to +15O°C

5.Magnetized: Axial,Diametrical or Multi-Poles

6.Advantage: High dimensional accuracy, good consistency, no follow-up processing, stable performance, shock resistance

Physical Properties of Injection Molded Ferrite:

Density: 3.08-3.88g/cm³

Tension Strength: 50-102( MPa)

Flexural Strength : 93-185( MPa)

Max. Operation Temperature: -40 to 150 (℃)

Hardness :118-120

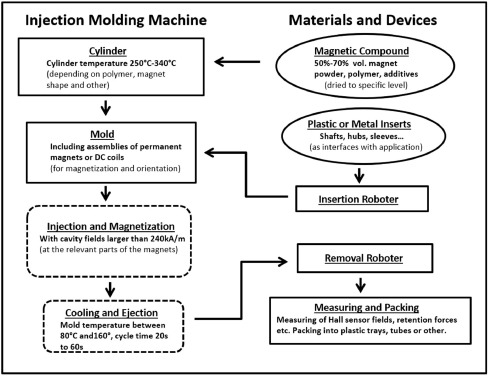

Production description:

Injection molded magnets are used in large quantities by different technical applications.

Their success can be explained by their high diversity of possible field distributions, their complicated shapes, their easy combinability

with other mechanical parts and by their economic way of manufacturing. Injection molded magnets are produced for magnetic

sensors,electrical machines, magnetic couplings, magnetic brakes and many other applications. In this chapter there will be

explanations of basicmaterial and system characteristics, manufacturing methods, magnetic polarization patterns as well as related

design methods of injection molded magnets. In addition, there are two sections explaining the use for magnetic sensors and for electrical machines.

Applications:

Fan Motors

Wiper Motors

EPS Motors

Starter Motors

Home appliance Motors

Industrial Motors

Motorcycle Motors

other DC Motors

Advantages:

*High remanence, high coercivity, high energy product, high performance and price ratio, easy to process various sizes and minimum specifications.

Why choose us?

Shorten the product design cycle and sample period,save the cost of project development

Need a Quote?

Please specify the following while ordering:

Shape, dimensions and tolerance

Magnetic specifications

Quantity (one time or repeating order)

Application / End use of the Magnet

Direction of Magnetization

Magnet acceptance inspection method

Magnetization requirements (magnetised) / (demagnetised)