Disc Neodymium Magnet With Countersunk Hole

1.Dimensions: Customized / Produce according to your needs

2.Materials: NdFeB,Grade N35 to N52 (M,H,SH,UH,EH AH)

3.Plating/Coating: Nickel,Zinc,Epoxy and etc.

4.Magnetization direction: Axial magnetized

5.Max operating temp.: 80 to 220 degrees celsius

These countersunk neodymium magnet can be used for a wide range of applications including door closures,tool hangers,and etc.

The hole can be drilled according to screws applicable to M3,M4,M5,M6,M8 or custom hole sizes,so the magnets to be conveniently fixed in place

How to choose the suitable NdFeB magnet?

If this is not your first time purchasing for magnets,then you know exactly what size,grade,coating and magnetization direction you needs.You can send us a RFQ directly by email or "leave us message",and we will respond to you within 24 hours.

If you're purchasing magnets for the first time,let's share the following informations:

1.Dimensions:

The size is determined by your applications.

2.Grade of NdfeB Magnet:

If your application is at room temperature only,the N series is the best choice,with a max operating temperature 80 degrees Celsius.

The higher the temperature of resistance of the magnet,the more expensive it is.For example,N35 grade and N35M grade have the same magnetic force,but the max opearting temp. of N35M is 100 degrees Celsuis.Please click here to check the properities of sintered neodymium magnet.

3.Magnetization direction:

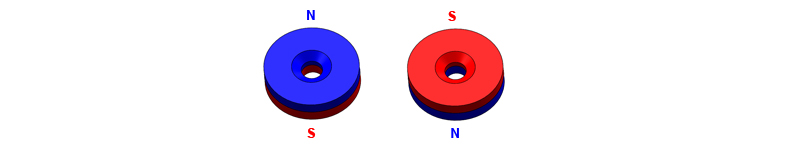

The magnetization direction of countersunk NdFeB magnet is axial magnetzied.In this way,the magnetic force of holding surface is always maintained at the maximum.

Sometimes they need to be used in pairs,that means one will have the north pole on the side with the large end of the hole and one will have the south pole on that side,so they will attract each other when they are screwed in.

4.Plating/Coating:

Nickel and Zinc coating are the most common,the salt spray test can meet the requirement of 24-48 hours.

Eopxy coating have excellent against humidity and salt spray environments,the salt spray test can reach 48-72 hours.

And there are other types of palting,like chrome(NiCuNi+Cr),gold(NiCuNi+Au),phospahted,passivation.

How to get a best quote?

After confirming the above four details,or if you have any futher questions,we would love to receive your email or messages.We will calcualte the price asap according to your order/sample quantity,and respond to your concerns.