Radial Oriented Sintered Neodymium Ring Magnet

1.Dimensions: Read the details

2.Materials: NdFeB,Grade N35 to N48, 35M to 45M, 35H to 42H, 35SH to 40SH, 35UH to 38UH,35EH

3.Plating/Coating: Nickel,Zinc,Epoxy and etc.

4.Magnetization direction: Radial magnetized

5.Max operating temp.: 80 to 220 degrees celsius

This type of neodymium ring magnets widely use for robotics and industrial automatic production line etc.

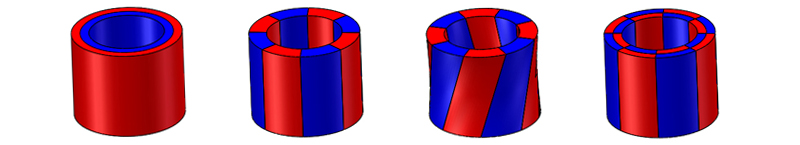

1.What is radial sintered neodymium magnet ring?

Ring magnet magnetized in radial direction is developed successfully which is using shaping method by new multipole radiation orientation,and meet differnet requirements of permanent motors.Fundamentally changed the past situation that radial ring magnet only relied on the magnetic tile assembly ,greatly improve the performance of motor.

The popular poles including:2 poles,4 poles,8 poles,10 poles,12 poles,etc,the number of poles and the skew angle were decided by the magnetizing tooling.This type of neodymium ring magnets widely use for robotics and industrial automatic production line etc.

2.The advantages of radial ring magnet

Radial oriented neodymium ring magnets have advantages.on assembly technique,the complete ring have less parts,can simplify and easily realize automatic assembly.The Out diameter higher precision,better coaxiality and verticality.Have flexible way to choose different ways of magnetizing,include magnetizing poles and angles.Also have highly reliable,no risk of magnet peel off.The most important things is to improve the motor performance,as this ring have very small air gap,motor have smoother operating performance with less noise and vibration.

3.The dimensions range of the sintered neidymium magnet ring

Dimension

Dimension Range(MM)

Tolerance (MM)

Outer Diameter

20-75 MM

+/-0.05 MM

Inner Diameter

15-68 MM

+/-0.05 MM

Wall Thickness

2-7 MM

+/-0.05 MM

Height

5-50 MM

+/-0.05 MM

4.Grade of NdfeB Magnet:

If your application is at room temperature only,the N series is the best choice,with a max operating temperature 80 degrees Celsius. In the N series,the N55 grade has strongest magnetic force,and is also the most expensive. Generally speaking,the N35 grade is relatively cost-effective and also have strong magnetic force.But which grade to choose depends on your pursuit of magnetic force or say application.

The higher the temperature of resistance of the magnet,the more expensive it is.For example,N35 grade and N35M grade have the same magnetic force,but the max opearting temp. of N35M is 100 degrees Celsuis

Please click here to check the properities of sintered neodymium magnet.

5.Magnetization direction:

Ring NdFeB magnet can be magnetized in two main ways(axial magnetized,diametrical magnetized),it all depends on your application requirements.

6.Plating/Coating:

Nickel and Zinc coating are the most common,the salt spray test can meet the requirement of 24-48 hours.

Eopxy coating have excellent against humidity and salt spray environments,the salt spray test can reach 48-72 hours.

And there are other types of palting,like chrome(NiCuNi+Cr),gold(NiCuNi+Au),phospahted,passivation.

How to get a best quote?

After confirming the above four details,or if you have any futher questions,we would love to receive your email or messages.We will calcualte the price asap according to your order/sample quantity,and respond to your concerns.