Disc/Round Neodymium Magnet

1.Dimensions: Customized / Produce according to your needs

2.Materials: NdFeB,Grade N35 to N52 (M,H,SH,UH,EH AH)

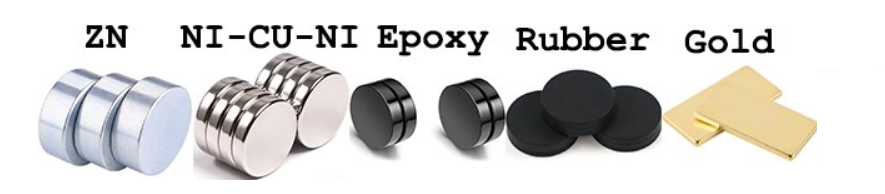

3.Plating/Coating: Nickel,Zinc,Epoxy and etc.

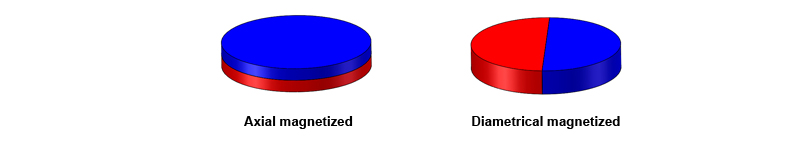

4.Magnetization direction: Axial magnetized,Diametrical magnetized and etc.

5.Max operating temp.: 80 to 220 degrees celsius

Round NdFeB magnet have a wide range of applications.

Even at a very small size,it is strong enough for many tasks.

Tiny size like D3x1mm,D4x2mm magnet and etc.

Middle size like D6x2mm,D10x1mm manget and etc.

Big size like D50x30mm magnet and etc.

How to choose the suitable NdFeB magnet?

If you're purchasing magnets for the first time,let's share the following information:

1.Dimensions:

The size can be customized,according to your requirement and here is the range of custom disc magnet sizes

| Diameter(mm) | Height (mm) | Tolerance(mm) | Direction of Magnetzation |

| ∮0.5-240 | H 0.5-80 | +/-0.05 - +/-0.1 | Axial Magnetized |

| ∮0.5-60 | H 0.5-40 | +/-0.05 - +/-0.1 | Diametrical Magnetized |

If you are not sure what dimension you need, we also accept trial orders for samples of different sizes and different grades.

2.Grade of NdfeB Magnet:

If your application is at room temperature only,the N series is the best choice,with a max operating temperature 80 degrees Celsius. Generally speaking,the N35 grade is relatively cost-effective and also have strong magnetic force.

But which grade to choose depends on your pursuit of magnetic force or say application.

The higher the temperature of resistance of the magnet,the more expensive it is.For example,N35 grade and N35M grade have the same magnetic force,but the max operating temp. of N35M is 100 degrees Celsuis,N35 is only degrees Celsuis.

Please click here to check the grade of Sintered Neodymium Magnet.

3.Magnetization direction:

Disc NdFeB magnet can be magnetized in two main ways, it depends on your application requirements.

4.Plating/Coating:

Nickel and Zinc coating are the most common,the salt spray test can meet the requirement of 24-48 hours.

Epoxy coating have excellent against humidity and salt spray environments,the salt spray test can reach 48-72 hours.

There are other types of coatings, such as chromium (nickel chromium alloy), gold (nickel chromium alloy + gold alloy), phosphating and passivation.

How to get a best quote?

After confirming the above four details,or if you have any further questions,we would love to receive your email or messages.We will calculate the price asap according to your order/sample quantity,and respond to your concerns.